Skip to content. Skip to main navigation.

Reliance on foreign fuels threatens our nation's economic, political, and environmental climate. CREST is an established research center dedicated to the development of renewable and alternative energy sources to reduce dependency on foreign energy. The UT System has made significant progress in developing efficient, less-costly, environmentally friendly energy processes. Examples include: biodiesel fuel processing, fabrication of solar cells, energy harvesting technologies, reducing the costs of coal liquefaction. CREST's mission is consistent with the theme of supporting local, state and nation development towards energy independence.

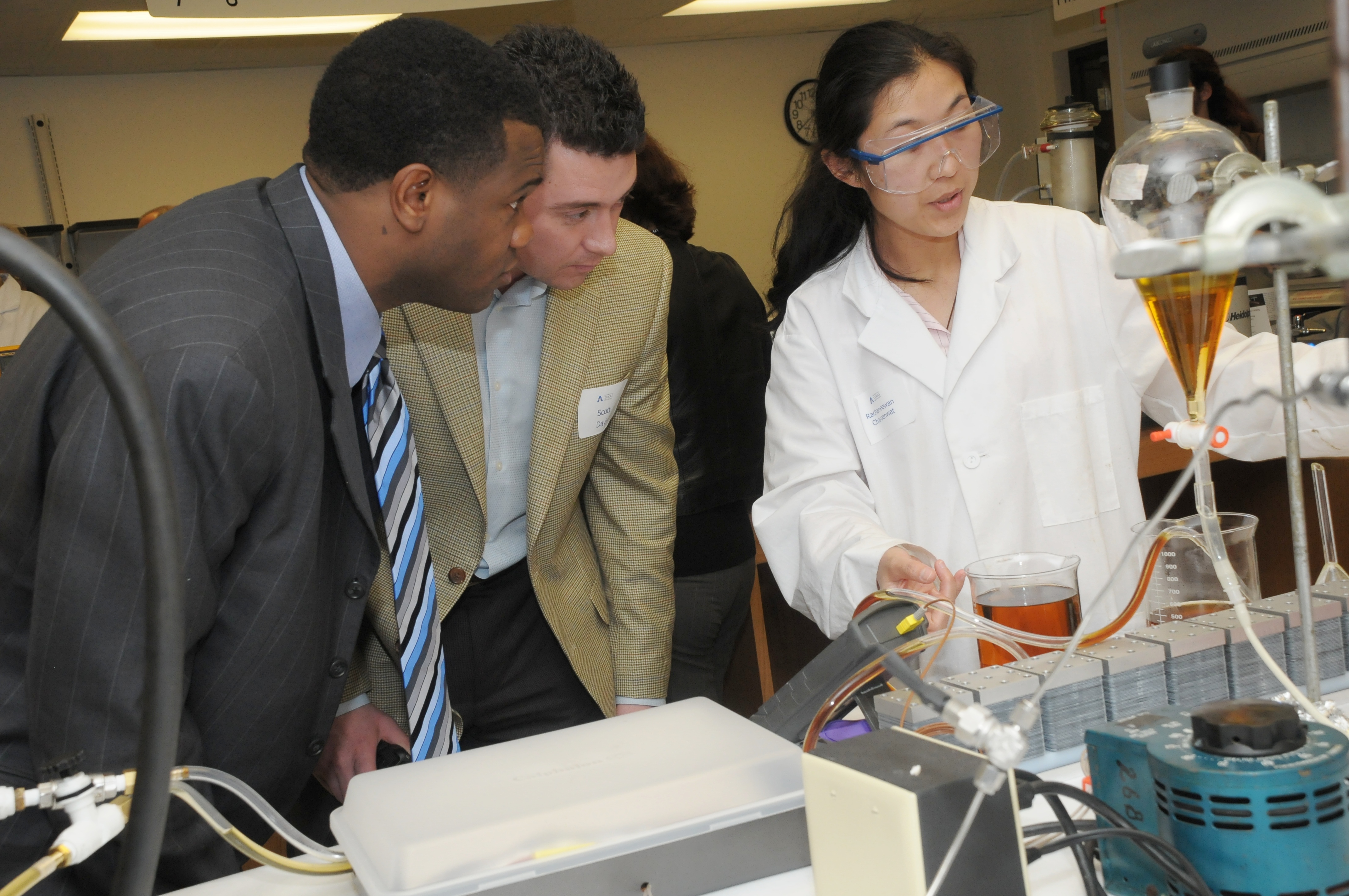

CREST provides a centralized facility with state-of-the-art instrumentation and coordination of research and development efforts between various faculty members. Examples include:

TXU and the Texas Commission on Environmental Quality recently developed a system-wide cap on key emissions for TXU's existing and proposed coal-fueled power plants. The cap will reduce total emissions by 20% of 2005 levels. To achieve these reductions, TXU is investing in Selective Catalytic Reduction (SCR) and Selective Non-Catalytic Reduction (SNCR) technologies. TXU has initiated two one-year projects with UT Arlington valued at $184K to develop a catalyst management program and conduct relevant environmental monitoring. Although sulphur dioxide and mercury will be constrained, the focus of this project is to minimize NOx emissions by optimally managing SCRs and related processes.

UT Arlington College of Engineering faculty members are developing a new biodiesel process for one of North Texas' oldest and most established oil distributors. The process, which incorporates nanotechnology and Texas cottonseed oil, will reduce the cost of biodiesel fuel production by at least 40 cents per gallon and cut the processing time for a gallon of biodiesel from 90 minutes to 4 minutes.