NASA invests in UTA materials research for safer flight

As NASA pushes toward a future in which air taxis and advanced aerial vehicles become part of everyday transportation, one challenge stands out above the rest: safety. Before these aircraft can fill urban skies, researchers must ensure they can withstand frequent takeoffs, landings and unexpected impacts without endangering passengers.

To help meet that challenge, The University of Texas at Arlington has received a three-year, $750,000 grant from NASA’s MUREP program to develop a new class of impact-resistant materials designed to protect next-generation aircraft during extreme landing or collision events.

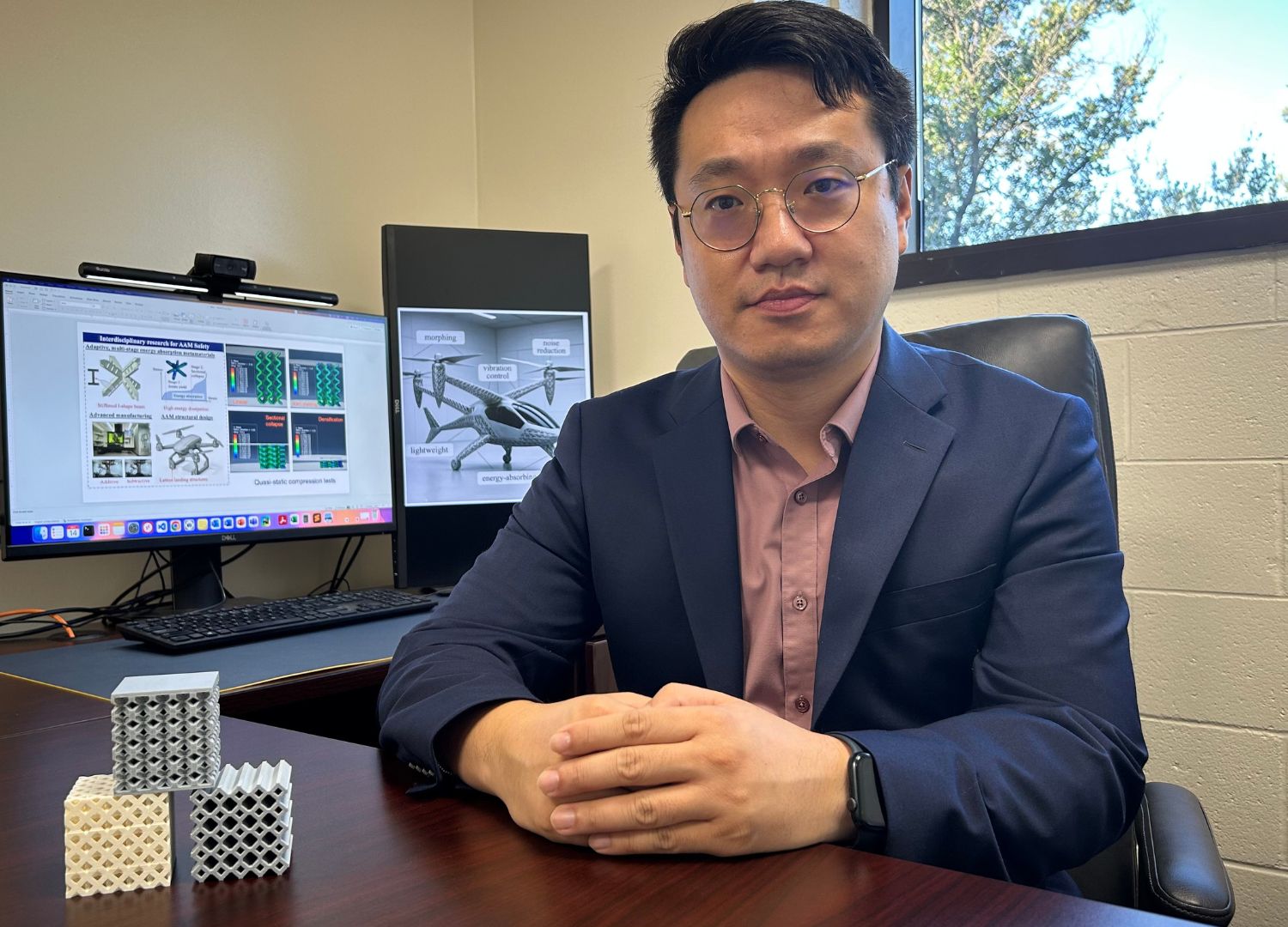

The project is led by Xin (Jeffrey) Liu, assistant professor in the Department of Mechanical and Aerospace Engineering, who also holds a joint appointment in the Institute of Predictive Performance Methodologies at the UTA Research Institute (UTARI) in Fort Worth.

“This project is trying to improve the safety of advanced air mobility aircraft,” Dr. Liu said. “Before we implement these new transportation technologies, we have to ensure that the structures, pilots and passengers are all safe.”

A New Material for a New Era of Flight

Advanced air mobility—which includes electric vertical takeoff and landing vehicles and urban air taxis—is a major focus at NASA. Unlike traditional aircraft, these vehicles are expected to take off and land frequently, more like running errands in an automobile than flying a commercial jet long distances. That shift creates new structural demands.

“Imagine every family having an aircraft,” Liu said. “You take off to work, land, then take off again to go home. That frequency of landing and takeoff creates very different safety challenges than traditional aircraft.”

Related: New flood maps, data aim to protect Texas communities

Liu’s team is developing a lattice metamaterial—a man-made structure fabricated through additive manufacturing—designed to dissipate impact energy in multiple stages. The material first absorbs energy through elastic deformation, allowing it to return to its original shape after normal landings. If a landing exceeds a certain load threshold, a second energy-dissipation phase activates to prevent catastrophic structural damage.

“The first step allows the material to recover its shape during soft landings,” Liu explained. “If there is a hard landing or collision, the second step dissipates a large amount of energy to reduce damage to the airframe and reduce impact loads on passengers and pilots.”

This multi-stage approach offers a key advantage over current impact-resistance systems, which often deform permanently after a hard landing and must be replaced. Liu’s goal is to develop materials that are both reusable and capable of handling extreme conditions.

“Current impact-resistance systems can break under repeated use or severe loading,” Liu said. “We want a new material that can be reused and still provide strong impact resistance under severe conditions.”

From Computational Models to Physical Testing

The research combines computational modeling, advanced manufacturing and experimental testing. By designing the material’s internal geometry at the microscale, Liu’s team can tailor its deformation behavior under different stress levels. The structures are fabricated using high-precision additive manufacturing and then tested to measure their real-world performance.

Related: Satellites and AI put UTA on front lines of flood fight

“It’s not a natural material—it’s designed,” Liu said. “We design the structure, fabricate it using additive manufacturing, and test whether it performs well for specific impact-resistance purposes.”

While the project is aimed primarily at advanced air mobility aircraft, the technology could also extend to space and satellite applications, where debris impacts pose similar risks.

A Collaborative Effort

Liu emphasized that the NASA project is a team effort, bringing together colleagues in mechanical and aerospace engineering, industry engineering, partners at the University of North Texas, and industry collaborators.

“This is teamwork,” Liu said. “We have strong collaborations inside our department, across UTA, and with external partners. Everyone is contributing to this project.”

Looking Ahead

For Liu, the grant represents both a professional milestone and an opportunity to contribute to a rapidly evolving transportation frontier.

“My background is in multiscale modeling of advanced materials,” he said. “When NASA announced calls for research to improve safety in advanced air mobility, I saw that this material had real potential to address that challenge. We applied and, fortunately, received the funding.”

Over the next three years, Liu and his collaborators will move the material from computational design to laboratory-scale testing—an important step toward safer aircraft for the future of urban air travel.

About The University of Texas at Arlington (UTA)

The University of Texas at Arlington is a growing public research university in the heart of Dallas-Fort Worth. With a student body of over 42,700, UTA is the second-largest institution in the University of Texas System, offering more than 180 undergraduate and graduate degree programs. Recognized as a Carnegie R-1 university, UTA stands among the nation’s top 5% of institutions for research activity. UTA and its 280,000 alumni generate an annual economic impact of $28.8 billion for the state. The University has received the Innovation and Economic Prosperity designation from the Association of Public and Land Grant Universities and has earned recognition for its focus on student access and success, considered key drivers to economic growth and social progress for North Texas and beyond.