Box 19017

UTA

Arlington, TX 76019

Deliveries

Woolf Hall Room 420

500 West First Street

Arlington, TX 76019

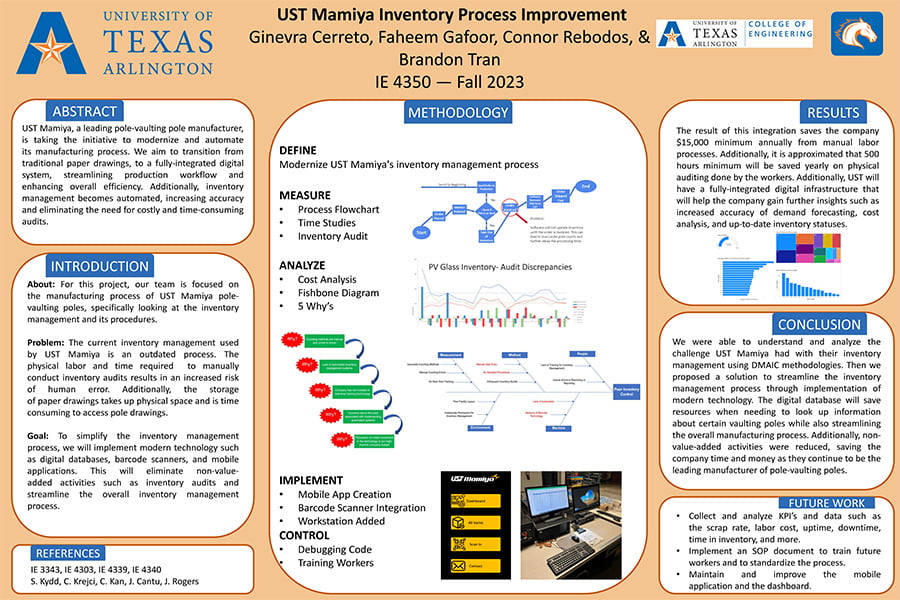

UST Mamiya, a leading pole-vaulting pole manufacturer, is taking the initiative to modernize and automate its manufacturing process. Our team have designed the transition from traditional paper drawings to a fully integrated digital system, streamlining production workflow and enhancing overall efficiency. The inventory management will be automated, thereby increasing accuracy and eliminating the need for costly and time-consuming audits.

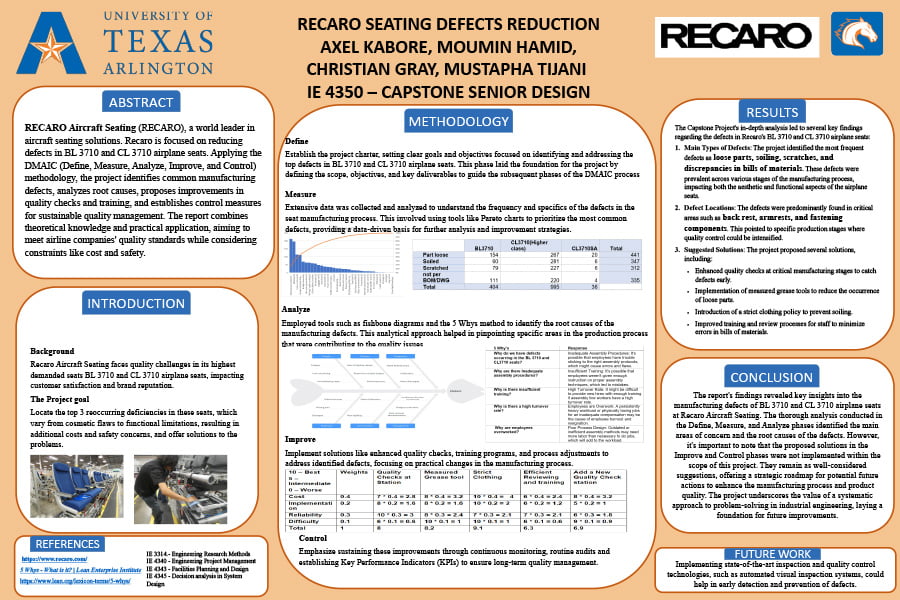

Recaro is focused on reducing defects in BL 3710 and CL 3710 airplane seats. Our team has applied the DMAIC (Define, Measure, Analyze, Improve, and Control) methodology, to identify several common manufacturing defects, analyzed root causes, designed several proposed improvements in quality checks and training, and established control measures for sustainable quality management.

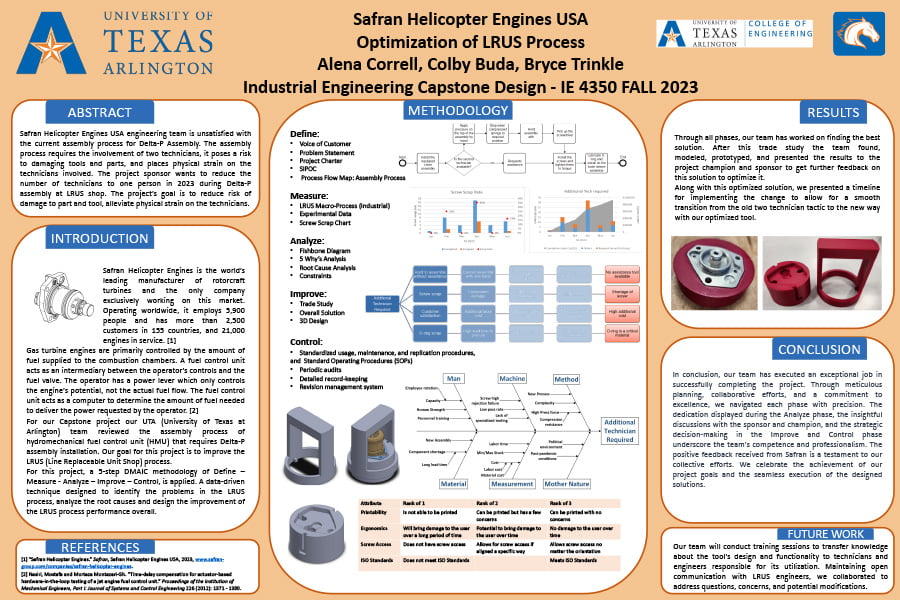

Our team improved the current assembly process for the Delta-P Assembly. We designed a tool that improves the assembly process, reduces damage to other tools and parts, and reduces physical strain on the technicians who put these parts together. The team modeled, prototyped via 3D printing, and verified the tool with assembly technicians and company engineers.

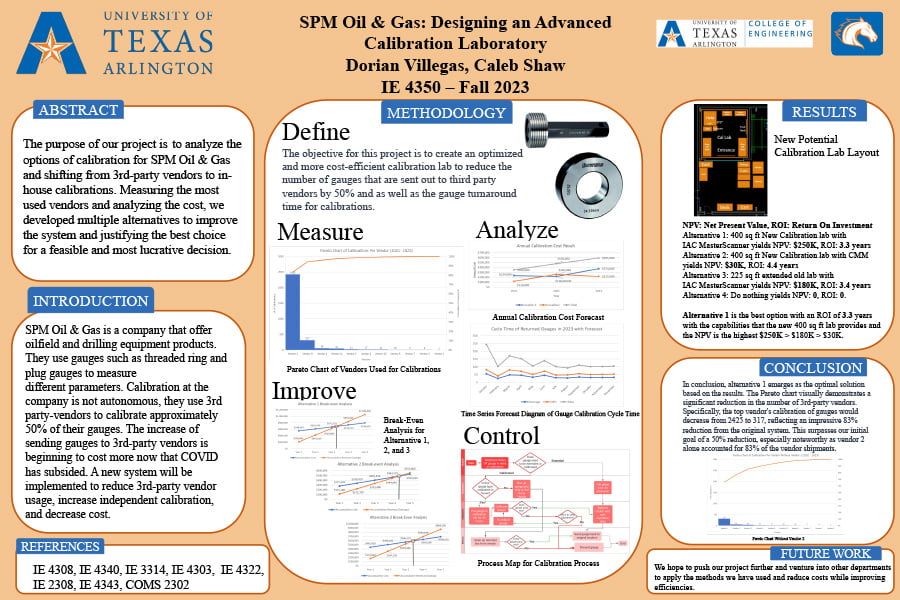

The purpose of our project is to analyze the options of calibration for SPM Oil & Gas and shift from 3rd-party vendors to in-house calibrations. We designed multiple alternatives of a laboratory to improve the calibration system and justified best choice.

The Fall 2023 Capstone group worked with the DFW Airport to design create a power audit plan to address the issue of inoperable charging ports within gate areas. With the knowledge gained in the IE curriculum the team was able to design an audit plan complete with training materials offering a systematic approach and standardization across all terminals to improve customer experience for DFW passengers.