Box 19017

UTA

Arlington, TX 76019

Deliveries

Woolf Hall Room 420

500 West First Street

Arlington, TX 76019

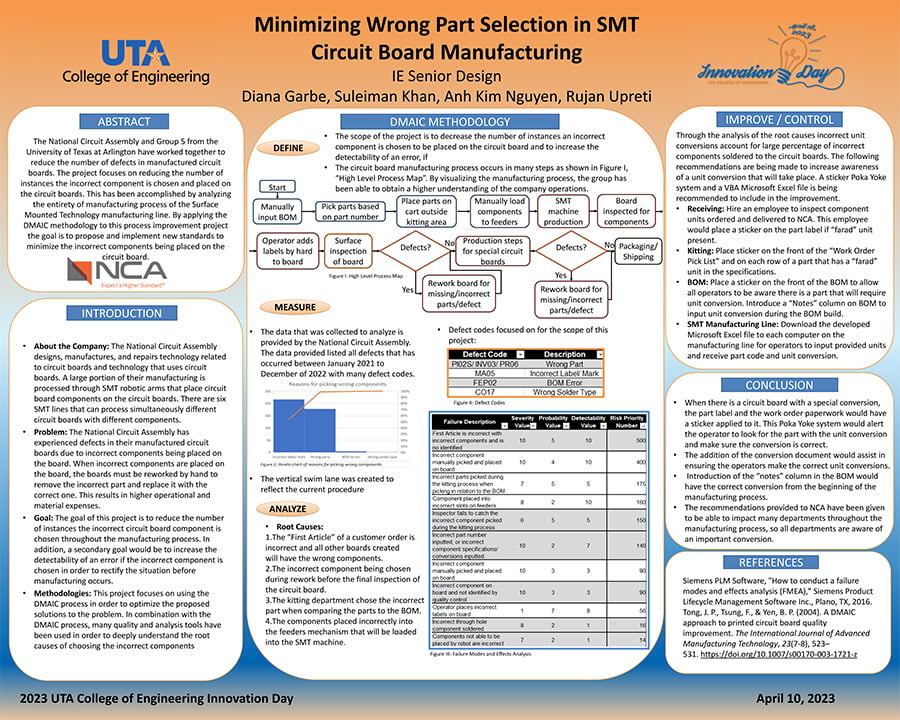

The National Circuit Assembly and Group 5 from the University of Texas at Arlington have worked together to reduce the number of defects in manufactured circuit boards. The project focuses on reducing the number of instances the incorrect component is chosen and placed on the circuit boards. This has been accomplished by analyzing the entirety of manufacturing process of the Surface Mounted Technology manufacturing line. By applying the DMAIC methodology to this process improvement project the goal is to propose and implement new standards to minimize the incorrect components being placed on the circuit board.

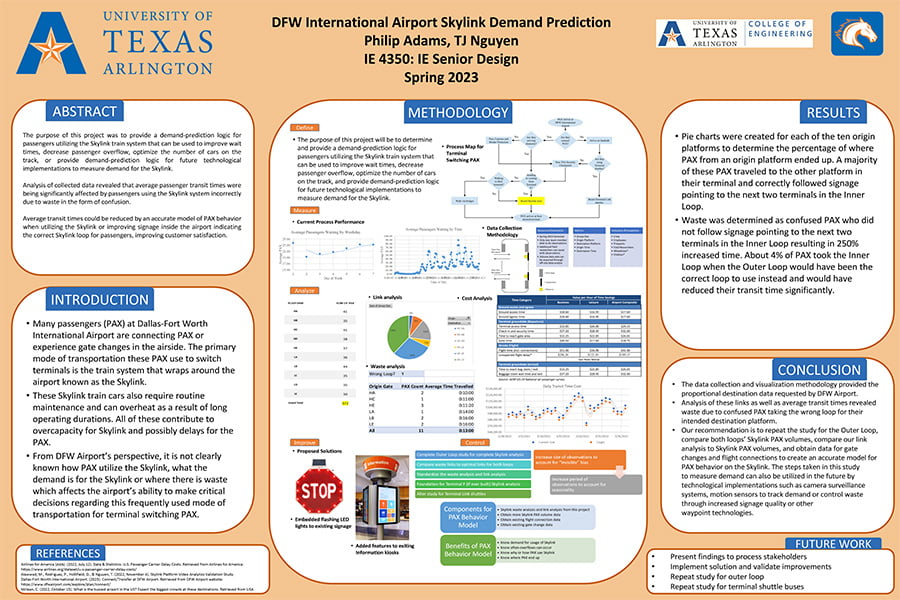

The purpose of this project was to provide a demand-prediction logic for passengers utilizing the Skylink train system that can be used to improve wait times, decrease passenger overflow, optimize the number of cars on the track, or provide demand-prediction logic for future technological implementations to measure demand for the Skylink.

The objective of our project was to increase the production capacity at Dollamur. We collected data on the production system and used it to create a discrete-event simulation in Simio. We then experimented with this simulation by applying the theory of constraints to develop and verify a solution.

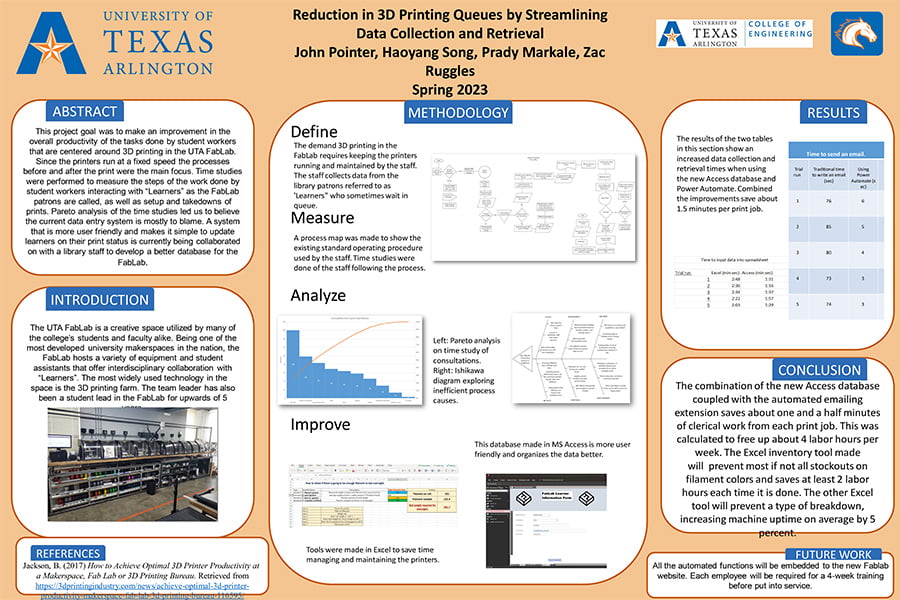

This project goal was to make an improvement in the overall productivity of the tasks done by student workers that are centered around 3D printing in the UTA FabLab. Since the printers run at a fixed speed the processes before and after the print were the main focus. Time studies were performed to measure the steps of the work done by student workers interacting with “Learners” as the FabLab patrons are called, as well as setup and takedowns of prints. Pareto analysis of the time studies led us to believe the current data entry system is mostly to blame. A system that is more user friendly and makes it simple to update learners on their print status is currently being collaborated on with a library staff to develop a better database for the FabLab

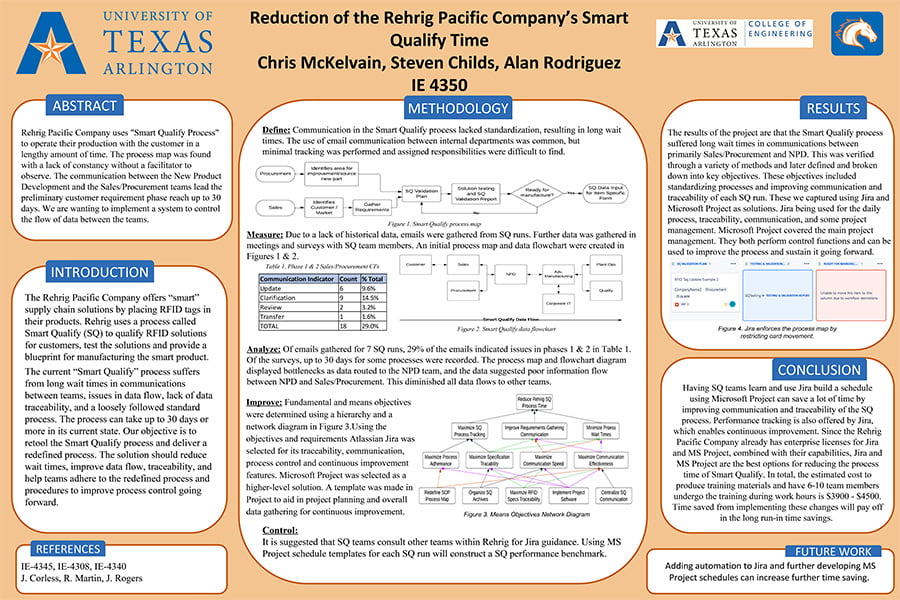

Rehrig Pacific Company uses "Smart Qualify Process" to operate their production with the customer in a lengthy amount of time. The process map was found with a lack of constancy without a facilitator to observe. The communication between the New Product Development and the Sales/Procurement teams lead the preliminary customer requirement phase reach up to 30 days. We are wanting to implement a system to control the flow of data between the teams.

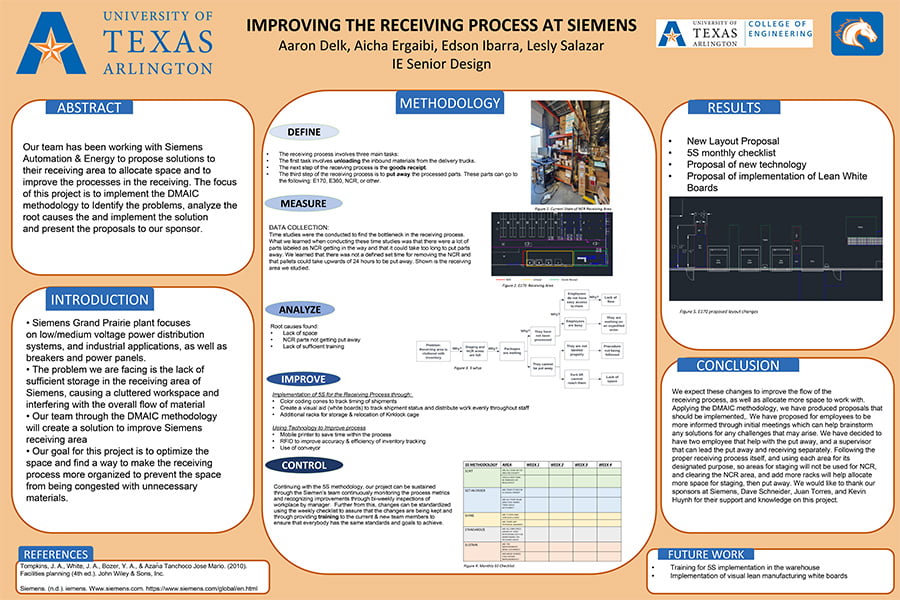

Our team has been working with Siemens Automation & Energy to propose solutions to their receiving area to allocate space and to improve the processes in the receiving. The focus of this project is to implement the DMAIC methodology to Identify the problems, analyze the root causes the and implement the solution and present the proposals to our sponsor.

The goal of our Capstone Project was to streamline UT Southwestern’s Rehabilitation Intake Process for external referrals received from other hospitals or skilled nursing facilities. We utilized the DMAIC Methodology consisting of the Define, Measure, Analyze, Improve, and Control Phases to complete our project. After measuring and analyzing their baseline process, our group determined the root causes to be communication breakdowns & delays within the patient data collection portion of the process. We produced a checklist that follows a new standardized process and will generate benchmark times for each step in the process that will allow for further improvements. We succeeded in reducing the overall process time and decreased the number of non-value-added activities within the process. We reduced the overall processing time by 13% and eliminated 3 non non-value-added steps and added 1 value added step.