Box 19017

UTA

Arlington, TX 76019

Deliveries

Woolf Hall Room 420

500 West First Street

Arlington, TX 76019

Our project serves as a testing ground for lean systems implementation starting with the Forklift Charging Station at the West Park facility. Our role was to design an intuitive and effective layout for the station while improving operations. Through an analysis consisting of 5 whys, pareto charts, and fishbone diagrams, we implemented various organization tools to aid in the productivity and organization of the area. Our project yielded an improvement of 65% using 5S assessment as a metric and has established a culture aimed at continuous improvement.

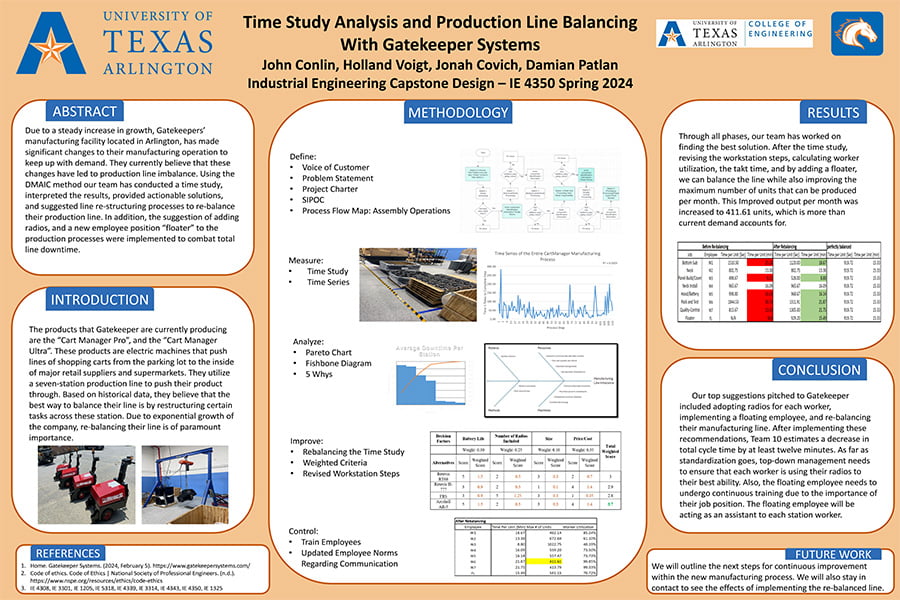

Gatekeeper recently moved their manufacturing line and added/subtracted different processes to start producing a newer model. These factors along with exponential company-wide growth and an ever-changing workforce has led to a less than optimally balanced production line. Our team pitch to Gatekeeper included adopting radios for each worker, adding a floating employee, and rebalancing the manufacturing line. After implementation, we estimate a decrease in total cycle time translating to an additional three units being made per day.

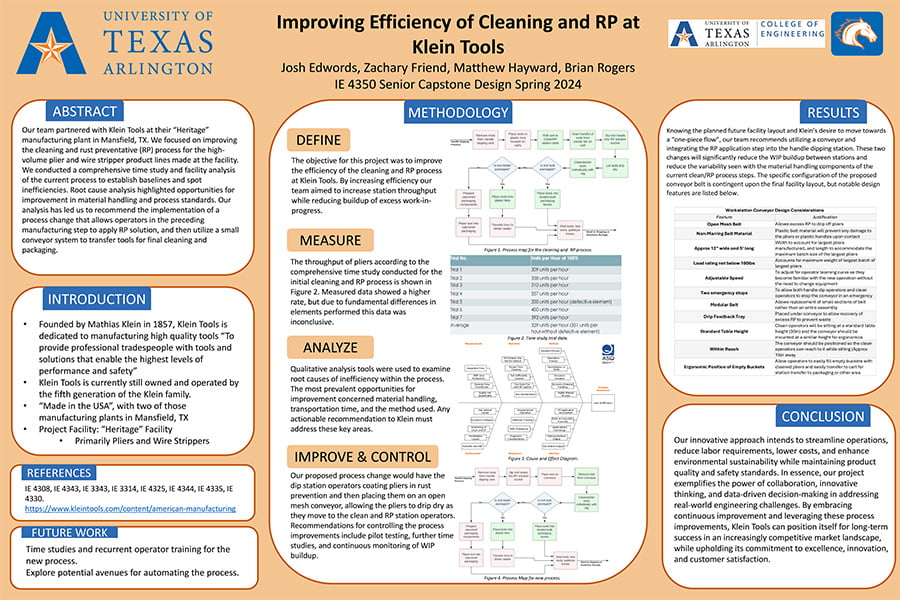

Our team's primary focus was improving the efficiency of the cleaning and rust preventative (RP) application process. Based upon the measurements we explored the root causes of inefficiencies, employing qualitative analysis tools to uncover critical insights. Our analysis revealed significant opportunities for improvement regarding material handling inefficiencies and product flow. These innovative process design improvements will streamline operations, reduce labor requirements, lower costs, and enhance environmental sustainability while maintaining product quality and safety standards.

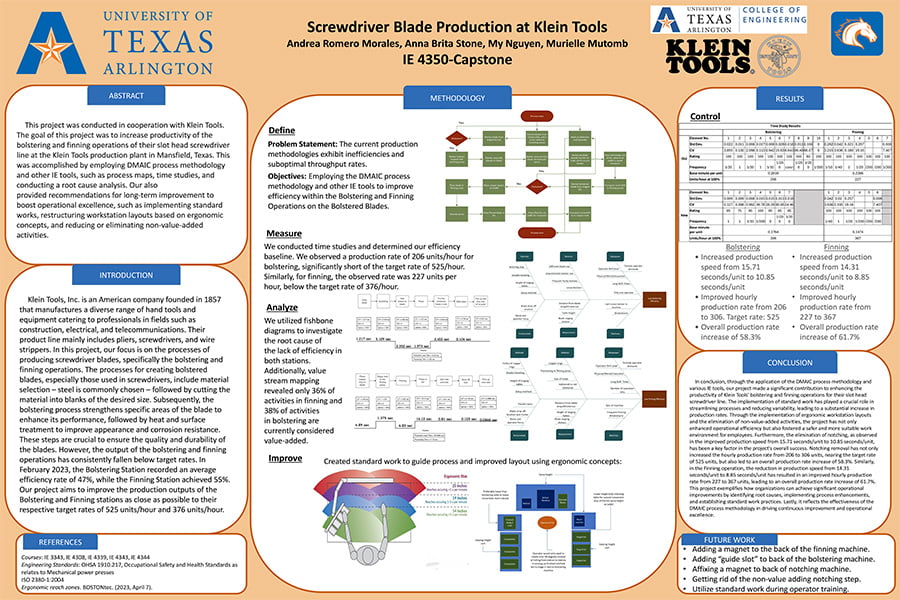

Our project aims to enhance efficiency in the bolstering and finning operations through application of the DMAIC process methodology. Leveraging industrial engineering tools and meticulous data collection, the project focuses on addressing observed inefficiencies. Analyses found that nonadjustable layout, wasted movements, and non-value-added processes were at the root of low station throughput. Processes were redesigned, tested, and recorded via standard work, and an improved layout was implemented. After improvements, a 48% production increase was found for bolstering and a 62% production increase for finning.

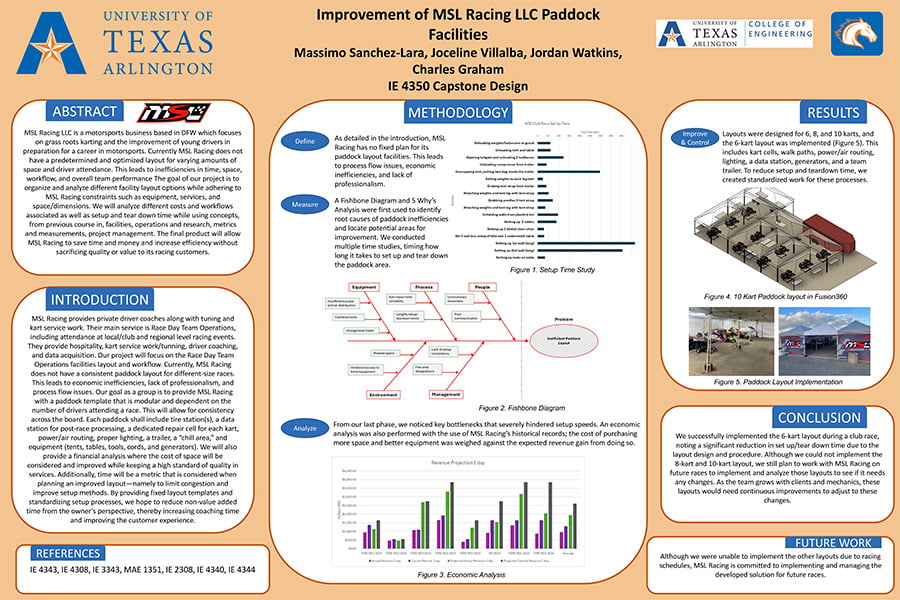

MSL Racing offers a range of services including private driver coaching, karting consulting, parts and service, and trackside race support. Currently, they do not have a consistent paddock layout for different-size karting events leading to economic inefficiencies, lack of professionalism, and process flow issues. Our team used the 5 Whys technique, an Ishikawa diagram, and process mapping to understand the process and explore potential causes for paddock inefficiencies and performed several time studies for setup/teardown process. This data was interpreted to establish key areas for improvement. We analyzed cost and revenue data from events and designed a template with a CAD model for 6, 8, and 10 kart layouts while maximizing space utilization and maintaining high quality of service. We developed a standardized set of instructions for setup/tear down which has reduced time and labor. Utilization increased across the board for service such as pit stalls, walkways, hospitality, food, data, and tire station. Based on customer feedback the new layouts and setup/teardown instructions have been a great improvement to overall performance, organization, and professionalism of the team.

Our project is to study a potential new washer system which will avoid having operators exposed to harsh chemicals as an improvement to hand washing the frames manually. We will evaluate how adding this washer system will impact the rest of the frame assembly line through various analyses, design a balanced line and standard work, and determine if throughput will be affected. We have been able to successfully provide National Door Industries, Inc. with multiple design recommendations for improvement and methods to ensure that the impact resistant frames (IRF) line is continuously improving. When implemented they will have a huge effect on cost efficiency. Rebalancing the line for two operators who will work the most value-added tasks justifies the cost of both operators.

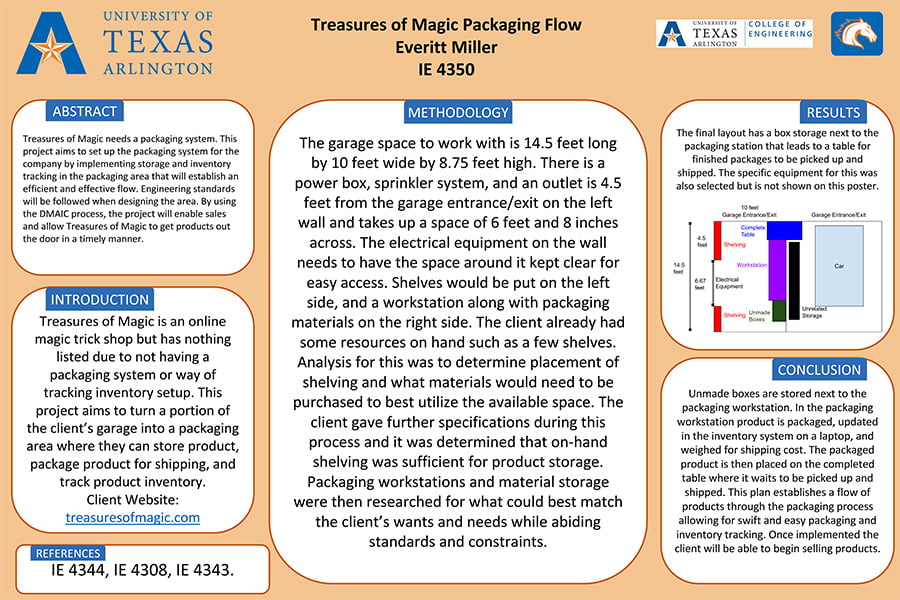

Treasures of Magic, an online magic trick store has set up a website for selling products but needs a packaging space to prepare items for shipment as they currently do not have one. This project has designed a packaging system and storage/work area that will establish an efficient and effective flow.

The UTA Special Collections (SPCO) division of the UTA Library confronts critical inefficiencies over the past fifty years leading to operational bottlenecks. Our project has tackled these issues head-on by using DMAIC. After conducting time studies to gather data on the current state of operations, we have identified specific areas where time was being lost. Our findings revealed that careful reorganization could lead to a significant decrease in wasted time. The newly designed SPCO layout has led to a remarkable 30.43% reduction in the travel time of catalogers. This efficient configuration signifies a leap forward in the operational workflow and promises a more effective use of the archival space.